SMED principle: Stop Wasting Time and Money on Changeovers

Following SMED is, in an ideal world, shared across multiple levels. The operators performing the tasks, supervisors overseeing the process, and management providing resources and driving continuous improvement. But what is SMED in plain English? SMED, or Single-Minute Exchange of Die, might sound technical, but the idea is simple: make changeovers fast. Really fast. We're talking about getting your machines switched over from making Product A to Product B in under 10 minutes.

If a factory is dealing with supply chain headaches, labor shortages, and constant pressure to boost profits it needs solutions that deliver real results. That's where SMED comes in. It’s a powerful, practical system for slashing changeover times – and unlocking hidden cash in your business. Think of it as a formula one pit stop for your production line!

Summarize with AI

Think of it like this:

Old Way: Changing a tire with a lug wrench, jack, and a lot of sweat.

SMED Way: A NASCAR or an F1 pit crew with coordinated teamwork, specialized tools, and a laser focus - from over a minute long pitstops in the 1960s to under 2 seconds in the 2020s.

The goal? Like in racing! To eliminate wasted time, and in manufacturing to boost production, and make your company more agile.

Why Should YOU Care about SMED?

Especially when you know about Kaizen - a Lean Principle. Well, Kaizen is a continuous improvement mindset and philosophy focused on gradual, ongoing positive change across an organization, while SMED (Single Minute Exchange of Die) is a specific, structured tool or methodology used to reduce machine setup and changeover times in manufacturing.

Faster changeovers are great, but they need to translate to real dollars. Here's how SMED can directly impact your company's profitability:

More Uptime = More Output: Less time spent on changeovers means more time cranking out products and fulfilling orders. This directly impacts revenue.

Smaller Batches, Happier Customers: Be more responsive. SMED lets you efficiently handle smaller production runs, meeting customer demands without tying up huge amounts of capital in inventory.

Reduced Inventory Costs: Less inventory sitting around collecting dust means reduced storage costs, lower risk of obsolescence, and more cash flow.

Improved Quality & Reduced Waste: SMED standardizes the changeover process, decreasing the risk of errors, defects, and wasted materials.

Increased Flexibility and Scalability: SMED allows manufacturers to react quickly to changing market demands.

Employee Satisfaction: Streamlined processes make life easier for your team, reducing frustration and improving morale.

Increased Availability: meaning less downtime. Faster and more efficient changeovers mean machines spend less time idle. This maximizes equipment uptime, ensuring your production lines are always ready to operate when needed, boosting overall capacity and reliability.

The SMED Secret: Internal vs. External – The Key to Unlocking Speed

The core of SMED is understanding the difference between internal and external setup:

Internal Setup: Tasks that must be done when the machine is stopped (e.g., removing a die, making critical adjustments).

External Setup: Tasks that can be done while the machine is running (e.g., gathering tools, preheating dies, preparing materials).

The name of the game? Convert as much internal setup to external setup as possible. It's like prepping all your ingredients before you start cooking – it's amazing how much time it saves!

How to Implement SMED: 5 Actionable Steps

Here's a practical roadmap to get you started with SMED:

Pick a Pilot: Don't try to overhaul everything at once. Select one machine or process that has a significant changeover time and offers clear potential for improvement.

Record Everything: Videotape a complete changeover process. This provides a clear baseline and helps identify wasted time and unnecessary steps.

Analyze and Separate: Break down the changeover into individual steps and classify them as internal or external.

Brainstorm and Convert: Challenge the status quo. How can you move internal tasks to external? Think creatively about tooling, preparation, and process improvements.

Streamline and Standardize: Simplify the remaining internal tasks. Use quick-release fasteners, standardized settings, and visual aids to reduce errors and wasted motion.

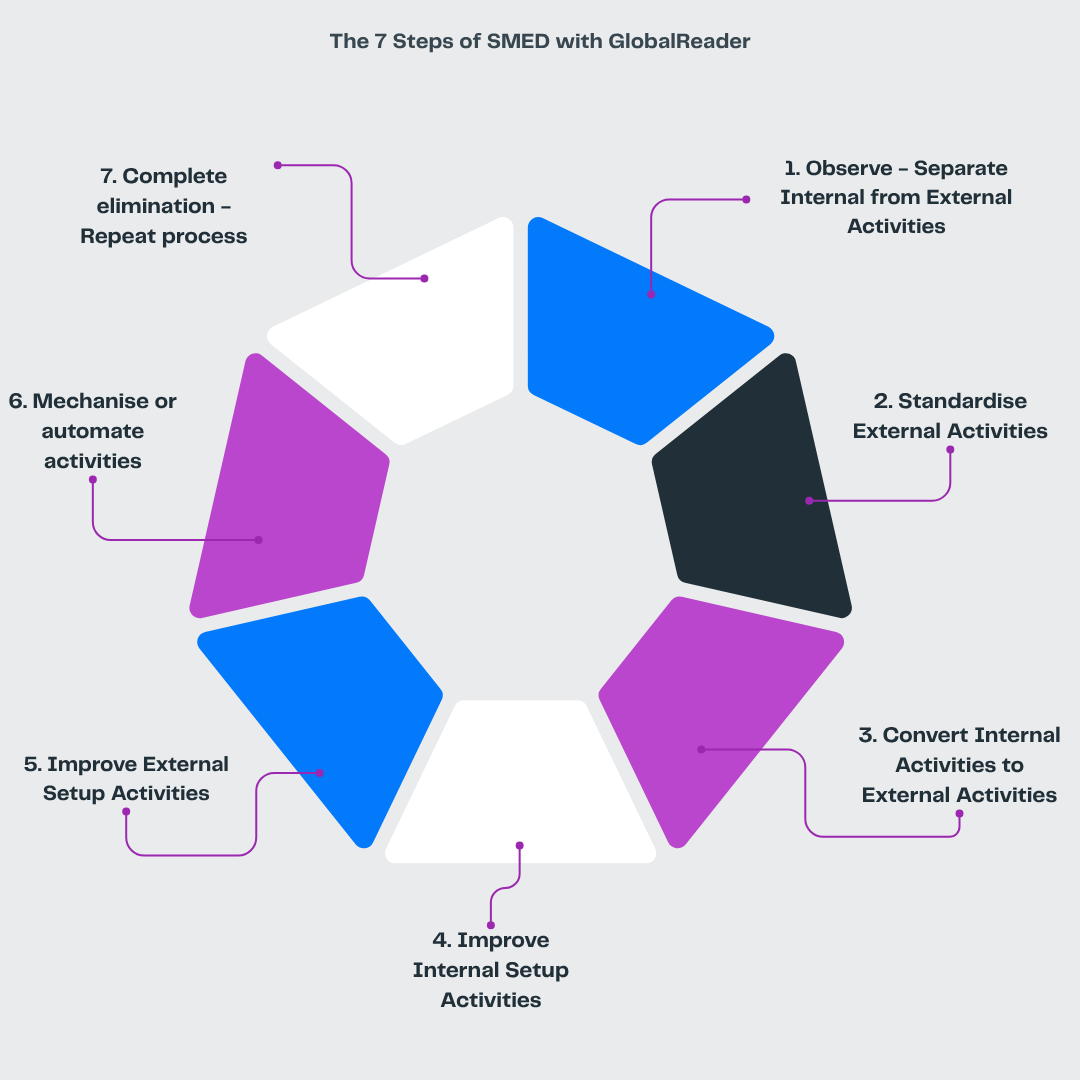

The 7 Steps of SMED in Order

The full 7 steps of SMED provide a structured approach to systematically reducing setup times. Each step builds on the previous one, helping teams move from simply identifying setup activities to eliminating them entirely.

Separate internal from external activities – Identify which setup tasks can be done while the machine is running.

Standardise external activities – Prepare tools, materials, and instructions in advance to ensure consistency.

Convert internal activities to external – Redesign or rearrange tasks so they can be performed before or after machine stoppage.

Improve internal setup activities – Simplify and shorten the remaining internal tasks.

Improve external setup activities – Make external steps faster and more reliable with better organisation and layout.

Mechanise or automate activities – Introduce tools, fixtures, or small automation to make changeovers smoother.

Complete elimination – Challenge the need for certain setup activities altogether through design or process innovation.

When teams apply these seven steps, setups evolve from long, unpredictable changeovers to quick, repeatable processes — maximising machine uptime and improving Overall Equipment Effectiveness (OEE).

SMED in Action: Real-World Examples that Inspire

Let's look at 2 businesses that are far apart from each other:

Automotive Supplier: A parts supplier reduced changeover times on a stamping press from 4 hours to under 30 minutes by implementing SMED. The result was a 20% increase in production capacity and a significant reduction in inventory costs.

Restaurant Chain: A restaurant chain uses SMED to optimize their lunch-to-dinner changeover, streamlining the process of switching ingredients and prepping stations. They reduced changeover time by 40%, resulting in faster service and happier customers.

Addressing Common Objections:

"We're too busy to focus on changeovers." – "I get it. But think of SMED as an investment that pays off in spades. Even a small reduction in changeover time can have a big impact on your bottom line."

"Our changeovers are already pretty efficient." – "There's always room for improvement. SMED is about continuous refinement, not just a one-time fix."

"It sounds complicated and expensive." – "SMED doesn't require a huge capital investment. Many improvements can be made with simple changes to processes and tooling. Start small, focus on quick wins, and build from there."

Your Path to Quick Changeovers and Higher Profits

SMED is a journey of continuous improvement. Here are a few ways to get started:

Start using GlobalReader. Our software has the tools to schedule and measure everything you need. Try our free demo and see for yourself.

Schedule a Plant Walk: Personally observe a changeover in your facility and identify areas for improvement.

Assign a SMED Champion: Empower a member of your team to lead the SMED initiative.

Contact a Consultant: If you need expert guidance, bring in a SMED consultant to assess your operations and develop a customized implementation plan.

Why SMED works perfectly?

SMED isn't just a technique, it's a mindset. It's about challenging the status quo, eliminating waste, and empowering your team to find better ways to work. It's a proven strategy for unlocking hidden profits, improving customer satisfaction, and building a more agile and competitive manufacturing operation. Stop wasting time and money on slow changeovers. Embrace SMED and transform your business.

Frequently asked questions about SMED

-

"SMED stands for Single-Minute Exchange of Die. Don't let the technical term scare you! It simply means reducing changeover times to single-digit minutes – less than 10 minutes. The goal is fast, efficient changeovers that boost productivity."

-

"SMED is a core Lean manufacturing principle with a proven track record. Companies across industries have used it to dramatically reduce changeover times, increase production capacity, lower inventory costs, and improve customer satisfaction. It's a powerful tool when implemented correctly."

-

"The SMED process typically involves these 5 steps:

Pick a Pilot: Choose a specific process to focus on.

Record Everything: Capture the current changeover process on video.

Analyze and Separate: Identify internal and external setup tasks.

Brainstorm and Convert: Find ways to move internal tasks to external.

Streamline and Standardize: Simplify remaining internal tasks."

-

"Absolutely! GlobalReader client, one car parts manufacturer reduced changeover times on a stamping press from 4 hours to 30 minutes using SMED. A restaurant chain streamlined their lunch-to-dinner switchover, cutting the changeover time by 40%. The possibilities are endless!"

-

"Not necessarily! Many SMED improvements can be made with simple changes to processes, tooling, and workflow. Start with low-cost, high-impact changes and build from there. A consultant can be helpful, but it's not always essential." GlobalReader Analytics and Operator are a great help for finding just these kidns of issues.

-

"Start by listing all the steps involved in a typical changeover. Then, classify each step as either internal or external. Identify potential improvements for each step. This list becomes your working template for future changeovers."

-

"You can often see significant improvements in changeover times within a few weeks of starting the SMED process. However, SMED is a journey of continuous improvement, so the benefits will continue to grow over time as you refine your processes."

-

"Even if your changeovers seem efficient, there's always room for improvement. SMED can help you identify hidden waste and streamline your processes even further. The potential benefits (increased capacity, reduced inventory) are often worth the effort."

-

"One of the biggest challenges is overcoming resistance to change. It's important to involve your team in the SMED process, explain the benefits, and empower them to contribute ideas for improvement. Teams that use GlobalReader often find that the Operators like the challenge of who does best and it’s all backed by data not assumptions"

-

"There are many resources available online, including articles, case studies, and training courses. Books on Lean manufacturing and the Toyota Production System also provide valuable insights into SMED. Look for resources from reputable sources with practical experience in SMED implementation." But if you like that then you are probably familiar with another Lean principle called Kaizen?