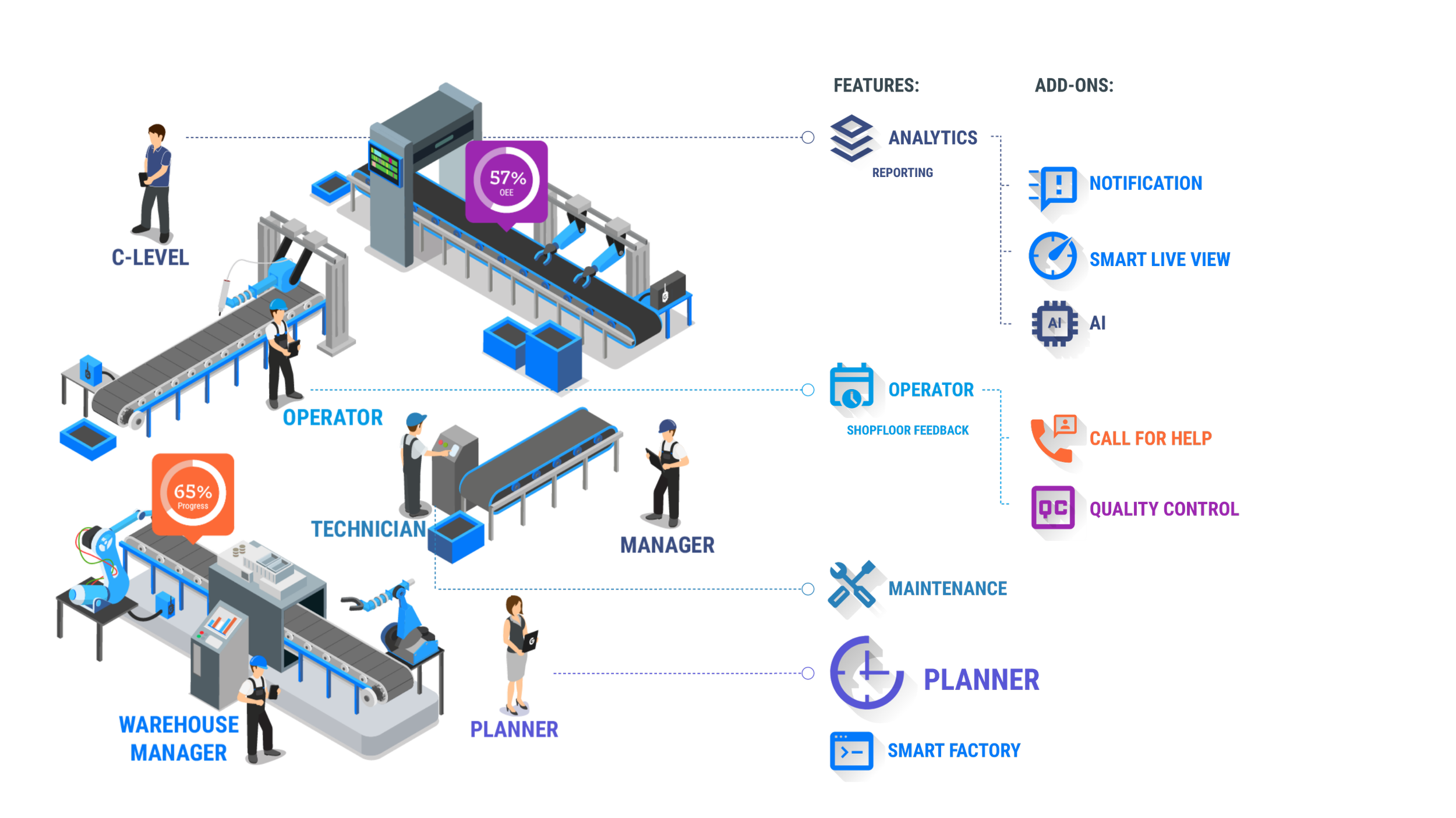

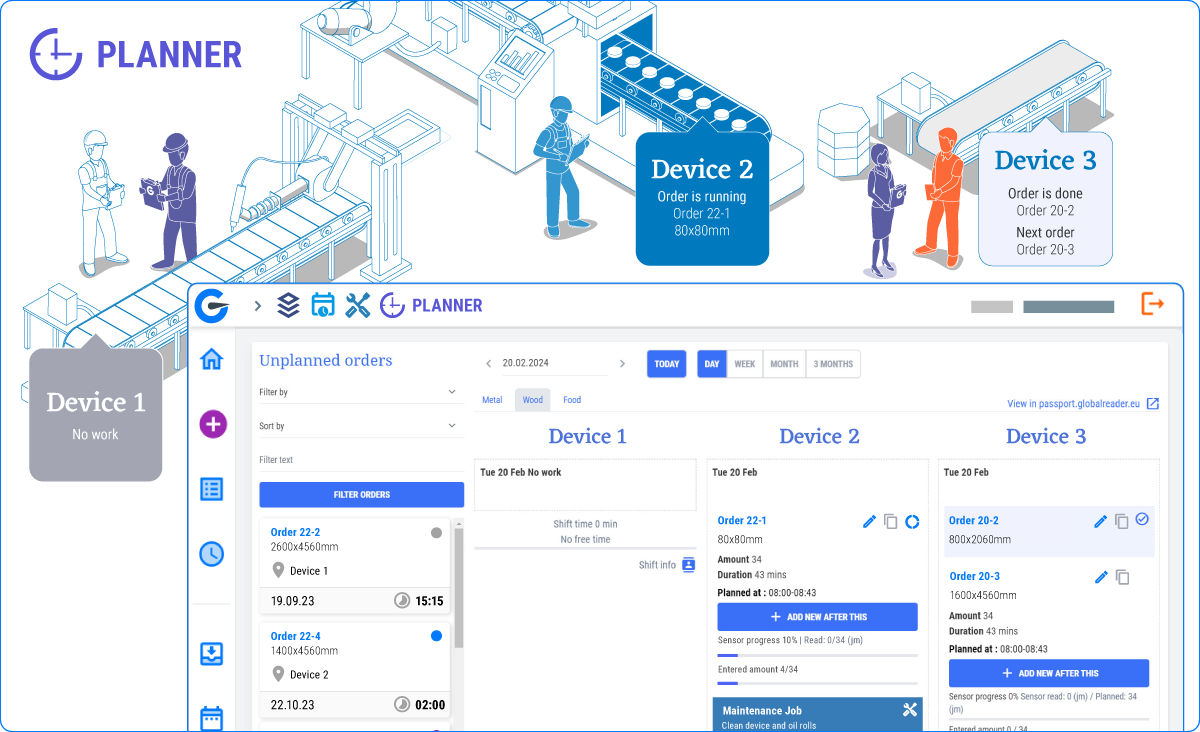

Where Planning meets the reality of the shop floor

Your go-to online work scheduling tool tailor-made for production planners. It seamlessly merges resource and order planning with real-time machine tracking, offering a unified ecosystem where your plans meet the reality of the shop floor.

Easily manage production planning

GlobalReader Planner is your ultimate online work scheduling tool, designed specifically for production planners. This innovative feature blends resource and order planning with real-time machine tracking, creating a unified ecosystem where plans meet reality head-on.

Simplified Workflow

With easy order addition, workstation assignment, and real-time monitoring, GlobalReader Planner simplifies the production planning process, reducing complexity and improving overall workflow..

Cost Reduction

By minimising production delays and resource wastage, manufacturers can reduce operational costs and increase profitability.

Real-Time Progress Monitoring

Monitor the progress of production plans in real time, receiving status updates on order production. This feature allows for quick responses to any deviations from the plan.

Efficient Work Allocation

Optimise works and schedules on the machines, this ensures that tasks are efficiently allocated, which reduces idle time and maximises resource utilisation.

Planner Overview

From Chaos to Clarity with Planner

We inspire industry leaders to collect data around their production resources:

to increase efficiency

to increase collaboration

to keep them ahead of their competitors

GlobalReader HARDWARE

Retrofit Hardware to any machine for data collection. Standard measurements:

> 3 data collection ports

> M12 connectors enable analog and digital readings

> Connected to cloud over WiFi, LTE or ETH

> Standard RS port for machine controller connection

> Data in 10 second intervals every 30 seconds sent to cloud

> Backup data for 30 days (if connection lost)

> DIY set-up

Anything else, just ask!

GlobalReader SOFTWARE

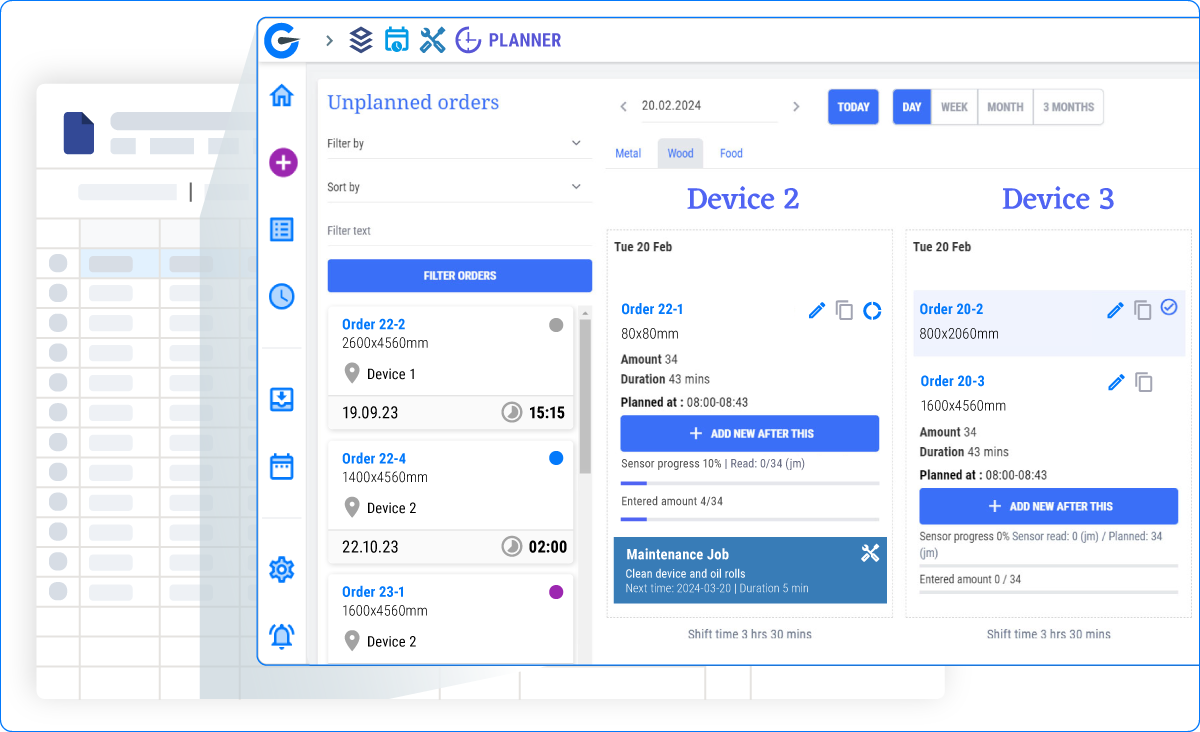

Move from cluttered Excel/Sheets to a clear, visual planning board

Gain a comprehensive view of all orders and their statuses at a glance

Organise and prioritise tasks with ease, improving workflow clarity

Transition from Excel/Sheets to Visual Planning

Smooth Transition:

Instant Overview:

Better Organisation:

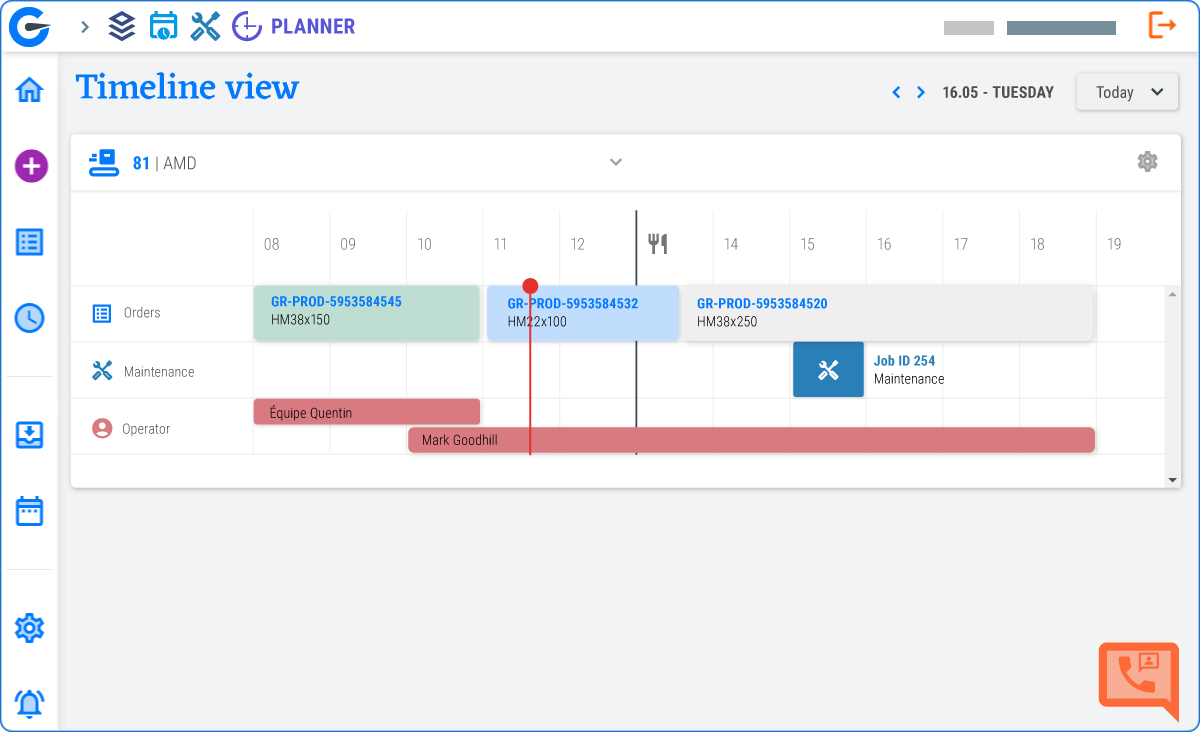

Real-time Adjustments for Dynamic Manufacturing

Easily rearrange orders across machines with drag-and-drop

Prioritise tasks for today, tomorrow, and beyond for optimal resource allocation

Minimise production interruptions with strategic maintenance planning

Flexible Scheduling:

Minimise Downtime:

Optimise Machine Use:

Increase Collaboration

Share real-time plans with Operator, ensuring paperless factory

Reduce misunderstandings and streamline operations with centralised information

Give your team the tools to know what's most important - Prioritise orders for Operators

Centralised Platform:

Clear Communication:

Empower Employees:

Smarter Planning with Real-Time and feedback

Compare planned vs. actual times to refine future planning accuracy

Use insights to give more exact timelines to customers and save money

Identify inefficiencies in planning to minimise wasted resources and time

Data-Driven Decisions:

Continuous Improvement:

Reduce Waste:

Boost efficiency by using factory Planner alongside other features

Complete control over manufacturing processes. From detecting potential issues with Analytics to taking proactive measures with Maintenance, entire production cycle becomes more efficient and reliable.

Complete Process Control

If a technical downtime is detected, technicians are instantly aware. Maintenance feature allows the technical team to address these issues within minutes.

Downtime Reduction

By sharing data, Planner and Maintenance enable manufacturers to incorporate maintenance tasks into their production schedules minimising downtime and disruptions.

Planning and Execution

Common Queries

-

GlobalReader Planner minimises production delays and resource wastage, ultimately leading to a reduction in operational costs. By optimising production planning, it helps manufacturers achieve a more efficient workflow, translating to increased profitability.

-

Real-time status updates in GlobalReader Planner provide production planners with invaluable insights. These updates allow you to stay informed about order progress, helping you make prompt decisions to ensure your production stays on track.

-

GlobalReader Planner works in harmony with Operator, Maintenance and Analytics, fostering collaboration between production planners, operators, and analysts. This synergy leads to a more cohesive and efficient manufacturing operation.

Let's Talk About Your Needs