Work-Hour Based Maintenance

Ready to cut downtime and boost efficiency? Let’s talk about bringing work-hour based maintenance to your factory!

Effective maintenance is critical to the reliability and efficiency of any production line. Performing maintenance too early consumes resources unnecessarily, while delays increase the risk of unexpected downtime. Traditional calendar-based schedules – weekly or monthly – do not account for actual machine utilization, leading to inefficiencies and operational risk.

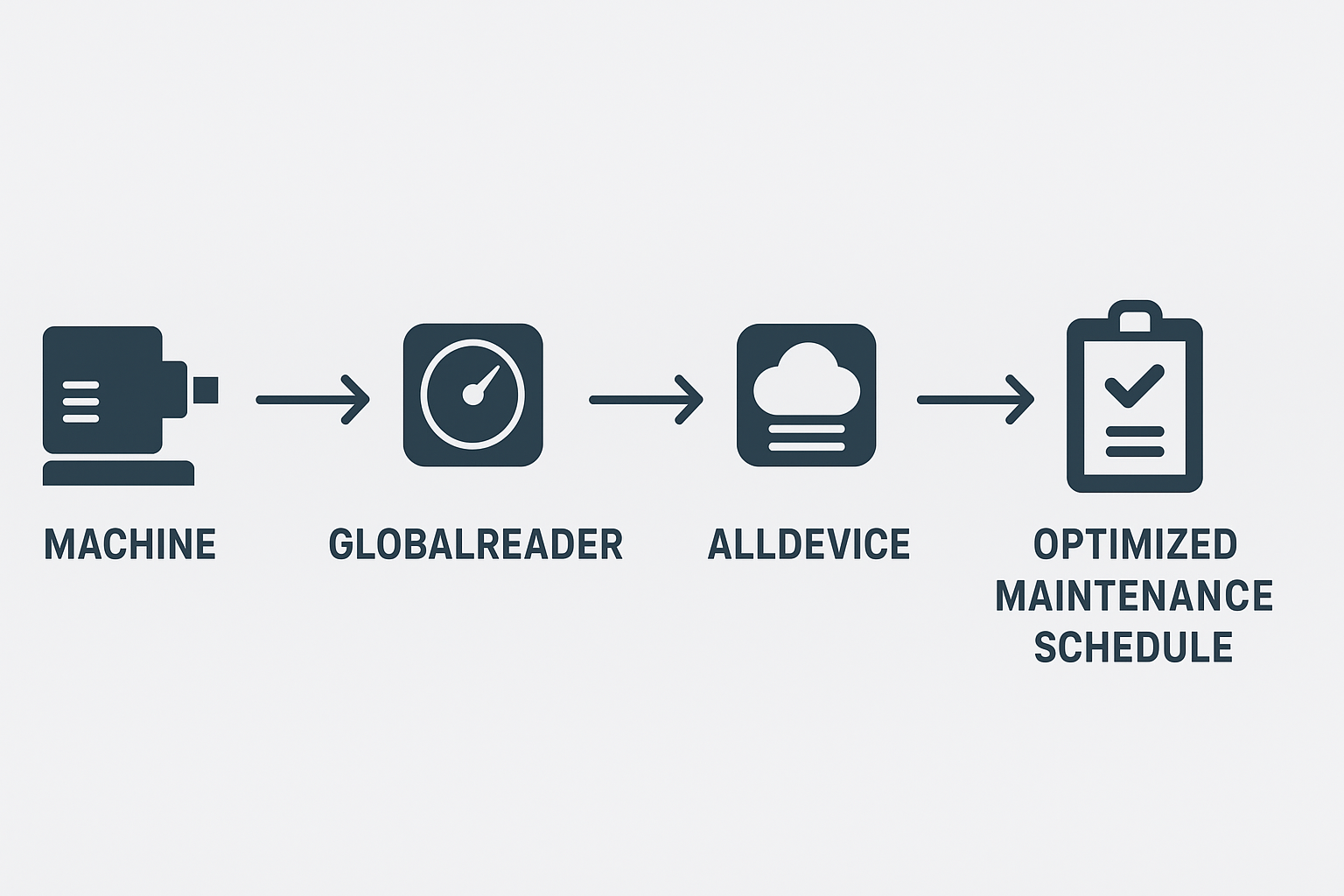

The solution: GlobalReader and Alldevice integration to adopt work-hour based maintenance.

Fixed-Time Maintenance: The Traditional Approach

Before we get to the solution we need to briefly cover other forms of maintenance schedules. Fixed-time maintenance, also called calendar-based maintenance, schedules service at regular intervals — such as weekly, monthly, or quarterly — regardless of actual machine usage. While simple to implement, it can lead to inefficiencies: maintenance may be performed too early, wasting resources, or too late, increasing the risk of unexpected downtime. This approach doesn’t account for variations in workload, which can result in either over-maintenance or overlooked issues.

Condition-Based Maintenance: Maintenance on Demand

Condition-based maintenance uses real-time equipment data — such as vibration, temperature, or performance metrics — to determine when servicing is necessary. This method ensures repairs are done only when truly needed, potentially extending machine life and improving efficiency. However, it requires advanced monitoring tools and data analysis, making it more complex to implement compared to fixed-time maintenance.

How Work-Hour based maintenance with GlobalReader and Alldevice integration Works

GlobalReader automatically collects machine operating hours and transmits this data daily to Alldevice. Using this information, Alldevice can be configured to calculate maintenance schedules based on actual workload. Maintenance is performed precisely when needed – not before, not after.

Real-Life Impact

Mechanics can focus on essential tasks rather than tracking schedules manually, improving efficiency and reducing operational stress.

According to our client:

“Previously, some machines received unnecessary maintenance because they were on idle, while others required attention sooner because their usage was higher than the fixed schedule accounted for, causing maintenance to be delayed. Now, maintenance occurs at the correct intervals based on real usage.”

Business Benefits

The results are evident: fewer unplanned stoppages, more consistent production, and better use of resources. Performing maintenance at the right time reduces downtime and indirectly saves costs, making planning more precise and avoiding unnecessary work. Over time, this also contributes to longer equipment life and more predictable maintenance costs.

Why Work-Hour Based Maintenance Fits Perfectly

Work-hour based maintenance combines the strengths of fixed-time and condition-based strategies. It adapts maintenance schedules to actual machine usage without requiring overly complex monitoring systems. This ensures service happens precisely when needed, reducing downtime and conserving resources. The GlobalReader and Alldevice integration make this process seamless, allowing production managers to proactively maintain equipment without extra effort.

Key Takeaways - Work-hour based maintenance benefits:

Right time, every time: Maintenance aligns with real workload.

Fewer surprises: On-time maintenance prevents unexpected breakdowns.

Efficiency and focus: Mechanics focus on value-adding work, not schedules.