I&T Metall Shopfloor Transformation with GlobalReader and Noom ERP Integration

Do you ever feel like your production data is scattered everywhere — some on paper, some in Excel, some in a system somewhere, and none of these systems actually “talk” to each other? We’ve all been there. Manual data entry, mistakes, and time-consuming reporting are constant headaches for production managers.

But what if we told you there is a way to get objective, real-time data directly from the shop floor, automatically linked to the production order in your ERP? This isn’t science fiction — it’s real-time ERP (Noom) and IoT (GlobalReader) integration.

Why Is This Critical for Manufacturing? Forget assumptions and rely on facts.

Imagine a situation where every machine cycle, every operator action, and every downtime reason is automatically recorded and connected to a specific production order. This isn’t just a “nice feature” — it’s critical information that finally gives you answers to questions production managers previously had to guess:

Measured Working Time and Quantity

How long did the job (order/operation) actually take? How many pieces did we really produce during the shift? No more operators’ “approximate” estimates. The data comes directly from the machine or from operator input through GlobalReader. This gives production managers objective facts — the foundation for accurate product costing.

Goodbye Paper and Excel

Operators start work on a GlobalReader touchscreen — and the event syncs instantly to Noom.No more manually filling out job sheets, entering data at the end of the day, or dealing with hidden Excel mistakes.

Time is money, and this system saves both.

Data You Can Trust

Human error is inevitable. But when data is collected through sensors and transferred automatically, you eliminate “polished” numbers or incorrect entries.True Product Cost and Profitability

This is the biggest value of the integration. When you know the exact time spent on each operation and the real quantity produced, you can calculate actual cost — not planned cost.You immediately see:

which products are truly profitable

where hidden costs are buried

This gives the company a strategic advantage in planning and decision-making.

What Do the Experts and Users Say?

““For Noom, it is critical to provide clients with accurate and up-to-date data that supports their business decisions. Integration with GlobalReader is a step forward in achieving this goal.

We can see how it helps clients reduce manual work, improve data quality, and ultimately make more informed decisions about their production processes.

Data moves smoothly, creating a unified system that is both flexible and robust.””

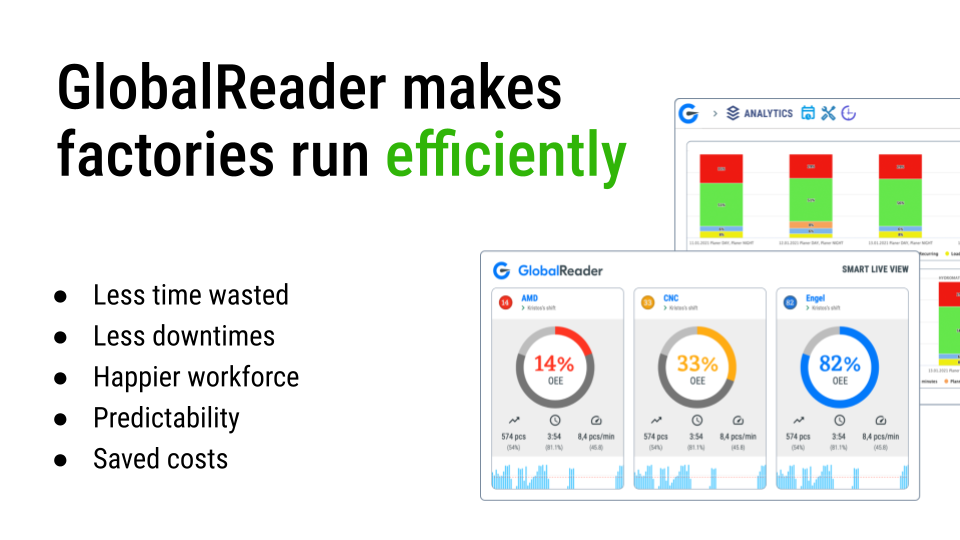

““GlobalReader’s goal is to bring real-time visibility from the shop floor directly to the production planner and production manager.

Integration with Noom means that the detailed information we collect (work cycles, downtimes, produced quantities) is no longer an isolated data set — it enriches ERP with objective, measured production data.

The GlobalReader Operator view gives operators a simple, intuitive tool and provides management with a clear overview of production to optimise every stage, every machine, every workstation, and overall efficiency.””

““The cooperation between GlobalReader and AstroBaltics went smoothly and efficiently.

The development teams participated actively in discussions and contributed ideas to find the most effective technical solutions for us. During the integration project, questions were answered quickly, suggestions were discussed constructively, and changes were implemented flexibly.

Thanks to this, the development process went smoothly, and the result met our expectations.

Typically, changes and new systems in production are welcomed cautiously and with some scepticism, but this time our operators accepted the solution positively — they appreciate that data entry has become faster and more convenient.

Thanks to the integration between GlobalReader and Noom, we now have a much more complete and accurate dataset about the entire production process. Real-time measured and collected data gives us a solid foundation for production planning, optimising resource usage, and forecasting workload more precisely.””

Ready for a Paperless Future?

IoT and ERP integration is not just an IT project — it’s an investment in the company’s future. It’s a step towards paperless, data-driven, fact-based and significantly more profitable production. If you’re tired of assumptions and want to see the real potential of your production, now is the time to act. Don’t wait for tomorrow — book a demo and see how this integration works with your company.

We also offer a test environment so you can try everything safely before going live! Click the button and see for yourself!