Manufacturing Efficiency with Data-Driven Insights

Manufacturers are constantly seeking ways to improve manufacturing efficiency. As Diimar Tarajev from Astro Baltics pointed out at a recent meetup, many companies are only now beginning to consider the importance of automation and digitalisation. Those who are already exploring these solutions have a distinct advantage.

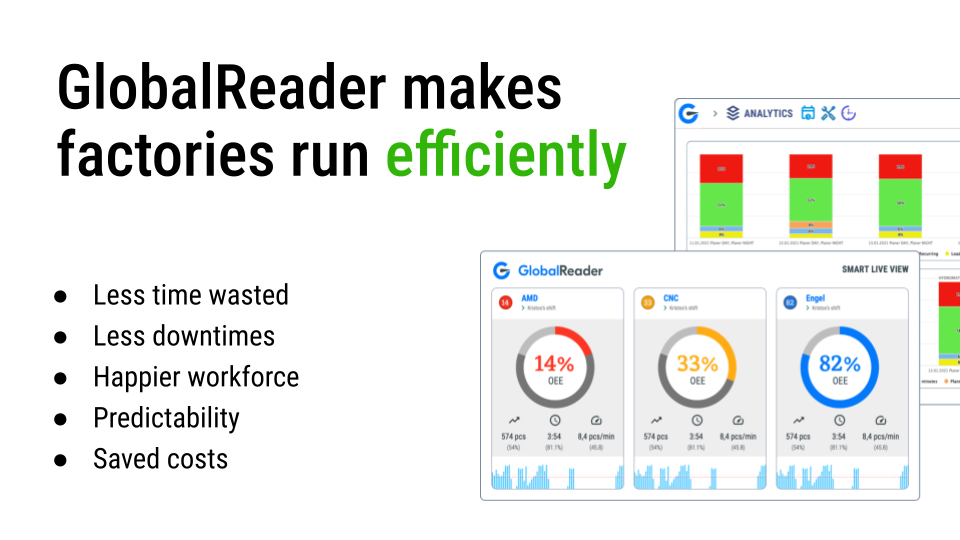

One key area of focus is manufacturing efficiency, encompassing everything from optimising workflows and reducing downtime to improving product quality and streamlining the supply chain. Improving manufacturing efficiency can lead to significant cost savings, increased output, and a stronger competitive position. This is where GlobalReader comes in. GlobalReader is a manufacturing execution system designed to provide real-time data and insights into manufacturing processes, helping companies identify bottlenecks, optimise resource allocation, and ultimately improve efficiency.

The 5 Steps to Digitalisation with GlobalReader

GlobalReader offers a step-by-step approach to digitalisation, with each stage building upon the previous one:

Connectivity: Connecting machines and equipment to collect real-time data.

Data Analytics: Analysing the collected data to identify trends, patterns, and areas for improvement.

Transparency & Collaboration: Providing real-time visibility into production processes for all stakeholders, enabling better collaboration and faster decision-making.

Predictive Capacity: Using data analytics to predict potential problems and optimise production schedules.

Culture Change: Fostering a culture of continuous improvement and data-driven decision-making.

Improve Manufacturing Efficiency: Integrate with MRP systems like NOOM, and Beyond

While GlobalReader offers a powerful standalone solution, its true potential is unlocked through integration with other systems. As Ergo Raudsepp from Astro Baltics explained, integrating GlobalReader with a Manufacturing Execution System (MES) like NOOM can provide a comprehensive view of the entire production process.

GlobalReader's strength lies in its flexibility and ability to connect with a wide array of existing systems. Through robust API (Application Programming Interface) connections, GlobalReader can seamlessly integrate with many popular MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems like Monitor G5, Microsoft Dynamics 365, and Business Central. This integration capability allows manufacturers to create a truly unified and data-driven environment.

The journey from a real-time factory tracker to a fully realized Manufacturing Execution System is made possible by this seamless data flow. Instead of operating as isolated entities, GlobalReader and your existing MRP/ERP systems work in harmony. GlobalReader captures granular, real-time production data from the shop floor, while the MRP/ERP system provides the overarching framework for planning, inventory management, and financial control. This synergy empowers manufacturers with enhanced visibility, improved decision-making, and ultimately, greater manufacturing efficiency.

What is MES?

Think of an MES like the central nervous system of a manufacturing operation. It connects all the different parts of the factory – machines, workers, materials, and processes – and provides real-time information about what's happening on the shop floor. Plus gives you a better overview of your factory OEE score.

By integrating GlobalReader with NOOM, manufacturers can achieve a seamless flow of information between the shop floor and the back office. This integration allows for:

Improved data accuracy: Eliminate manual data entry and reduce the risk of errors.

Real-time visibility: Get a clear picture of what's happening on the shop floor at any given moment through notifications or Smart Live View.

Better decision-making: Make informed decisions based on accurate, real-time data.

Increased efficiency: Optimise production processes and reduce downtime.

Furthermore, GlobalReader's API allows it to be integrated with other systems, such as:

Cloudics Laomees: Astro Baltics' warehouse management application.

Microsoft Dynamics and Microsoft Business Central: Popular ERP (Enterprise Resource Planning) systems.

Real-World Benefits Using Our Manufacturing Execution System MES Software

In the mentioned Astro Baltics meetup, Jaan Kraav shared a compelling example of how GlobalReader helped one of their clients improve manufacturing efficiency. By implementing GlobalReader and requiring operators to report the reasons for any downtime longer than one minute, the client was able to identify and address the root causes of these disruptions. As a result, they increased their production line's output by 40%. This demonstrates the power of data-driven insights in identifying and eliminating inefficiencies. This is just one of the case studies you can read about on our website.

How Data Visibility Helps Manufacturing Efficiency?

As Diimar Tarajev emphasised, simply collecting data is not enough. The real value lies in how that data is used. Companies need to analyse the data, identify trends, and implement changes to improve their processes. This requires a commitment to data-driven decision-making and a willingness to embrace new technologies.

Key Takeaways

Manufacturing efficiency is crucial for success in today's competitive landscape.

GlobalReader offers a step-by-step approach to digitalisation, helping manufacturers improve efficiency and optimise their processes.

Integration is key to unlocking the full potential of GlobalReader. Integrating with systems like NOOM, Cloudics Laomees, Microsoft Dynamics, and Microsoft Business Central can provide a comprehensive view of the entire production process.

Data utilisation is essential. Companies need to analyse the data collected by GlobalReader and use it to make informed decisions and drive continuous improvement.

By embracing digitalisation and leveraging the power of data, manufacturers can significantly improve their efficiency, reduce costs, and gain a competitive edge. You can start today by taking a look at our DEMO. It’s for free, so no financial commitment is necessary at first. We have a subscription based pricing model starting from 109€ per month to get you quickly started. The starter bundle comes with hardware and Analytics features.