Get a comprehensive overview about OEE

Deep Dive Into Digitalisation

Everything about Lean Manufacturing

Read GlobalReader Case Studies about OEE

Everything about Data Analysis

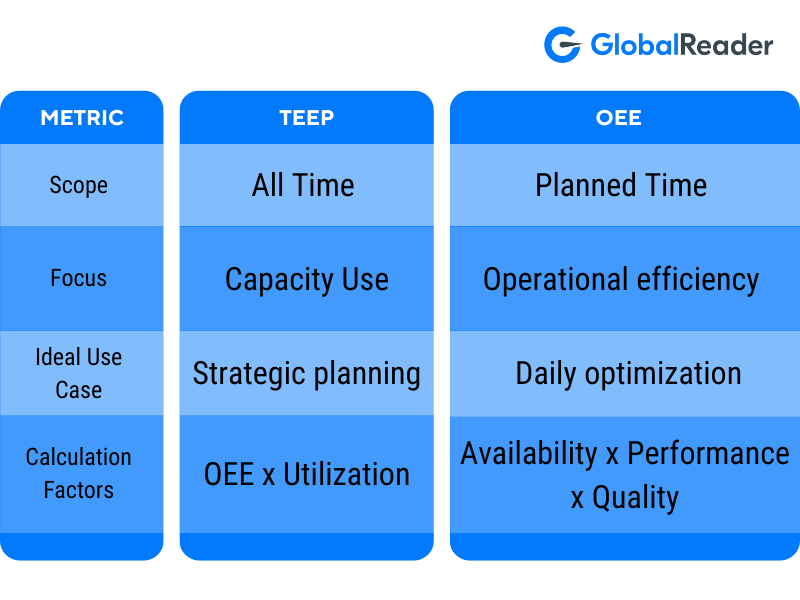

Everything about TEEP

All GlobalReader Posts

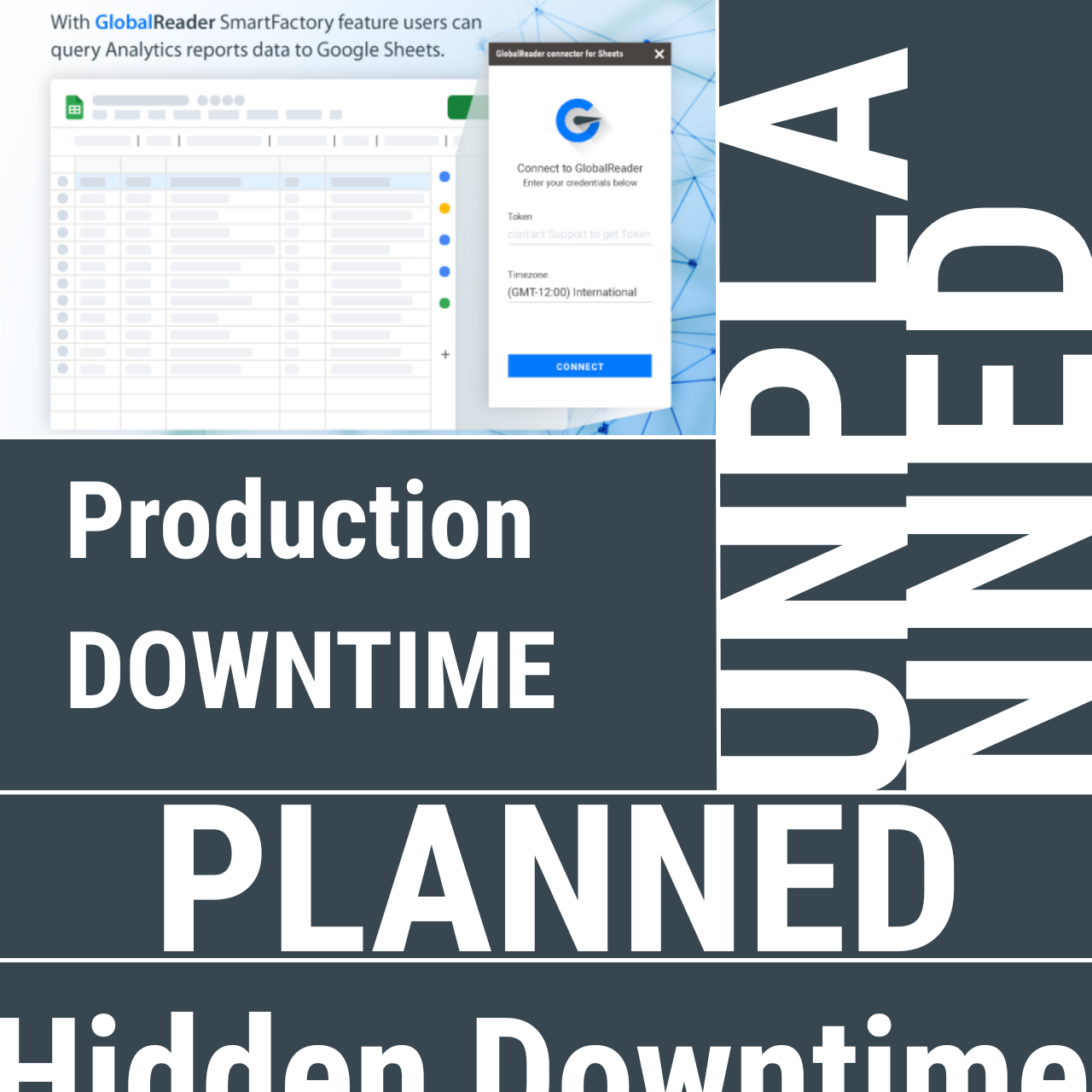

Manufacturing Downtime: Causes, Costs, and Prevention

Manufacturing downtime is any period when production equipment is not operating and producing goods. It's the gap between your planned production capacity and what you actually achieve.

Manufacturing Efficiency with Data-Driven Insights

Manufacturers are constantly seeking ways to improve manufacturing efficiency. Many companies are only now beginning to consider the importance of automation and digitalisation. Those who are already exploring these solutions have a distinct advantage.

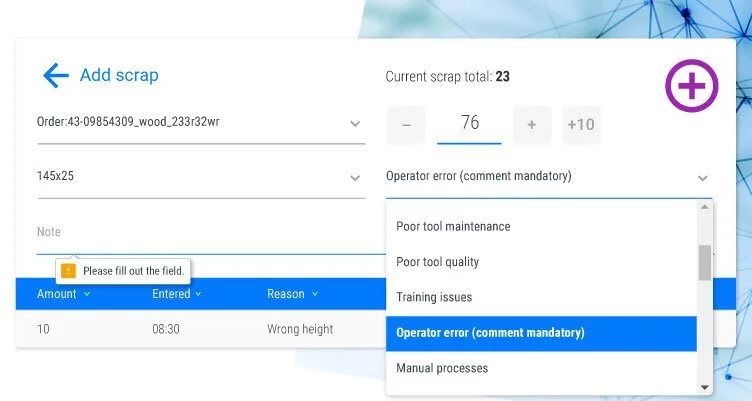

Cost Of Quality In Manufacturing

Cost of Quality (COQ) is a framework for quantifying all costs incurred by an organisation related to ensuring product or service quality, categorised into:

Prevention costs, such as training, process design and preventive maintenance, aimed at averting defects before they occur.

Appraisal costs, including inspection, testing and audit activities, undertaken to verify conformance to quality standards.

Failure costs, which encompass internal failures (scrap, rework and downtime) and external failures (warranty claims, returns and reputational damage).

By analysing COQ, a company gains visibility into how much it spends on maintaining versus rectifying quality, and can therefore identify where investments in process improvements will yield the greatest savings and performance gains.

How to Implement an OEE Improvement Plan: A Step-by-Step Guide

Implementing an effective OEE improvement plan requires a systematic approach, from assessing current performance to setting goals, optimizing processes, and engaging employees. By leveraging GlobalReader’s comprehensive suite of tools and services, manufacturers can gain real-time insights, predict and prevent equipment failures, and continuously improve their OEE. Start your journey towards higher efficiency and productivity with GlobalReader today.

Common Challenges in OEE Implementation and How to Overcome Them

OEE Implementation in a manufacturing environment can be transformative, driving significant improvements in productivity, efficiency, and quality. However, many companies face common challenges that can impede the successful adoption of OEE practices.

Top 10 Strategies to Improve OEE in Your Manufacturing Process

It is essential to improve OEE for manufacturing efficiency and profitability. By implementing these top 10 strategies, manufacturers can identify inefficiencies, reduce downtime, and enhance overall productivity. Start implementing these strategies today to see a marked improvement in your OEE and operational performance.

Overall Equipment Effectiveness (OEE): Definition & Guide

Interested in knowing what is overall equipment effectiveness? Good! When it comes to the question of what is Overall Equipment Effectiveness (OEE), we can say it is a crucial performance metric for manufacturers, measuring the percentage of manufacturing time that is genuinely productive. By evaluating the efficiency and effectiveness of equipment, OEE provides a comprehensive insight into how well a manufacturing operation is utilised. It encompasses three key components: Availability, Performance, and Quality, offering a clear picture of areas needing improvement.

Maximising Manufacturing Efficiency and Performance with OEE

Efficiency is crucial for competitiveness. One effective way to achieve this is through OEE. This blog post delves into what OEE is, how to calculate it, and its essential role in boosting productivity and driving continuous improvement.