What is Machine Availability

Machine availability is the percentage of time a machine or system is operational and ready to perform its intended task during available production hours, typically expressed as a percentage calculated as (Actual Operating Time / Planned Production Time) × 100.

Availability is a foundational component of OEE (Overall Equipment Effectiveness), alongside performance and quality metrics.

Summarize with AI

Why is Machine Availability important?

Machine availability dashboards benefit anyone responsible for keeping production running smoothly — especially factory managers, maintenance teams, and production planners. They provide instant visibility into which machines are running, idle, or down, allowing quick responses to issues and better scheduling decisions.

For management, they offer a clear overview of overall efficiency and equipment utilisation, helping identify bottlenecks and plan improvements. In short, these dashboards turn real-time machine data into actionable insights that boost uptime, productivity, and profitability across the factory.

“You can’t fix what you can’t see — and most quality losses are invisible until you track them in real time.”

The Three Pillars of OEE

Availability – How often equipment is running vs scheduled time.

Performance – How fast it runs compared to ideal speed.

Quality – How many units are good vs defective.

Impact on Operations

Without strong availability, even the fastest machines producing perfect quality can’t reach their full potential. Low availability results in:

Increased downtime

Lower throughput

Poorer ROI on equipment

[Read more: The Availability Pillar of OEE]

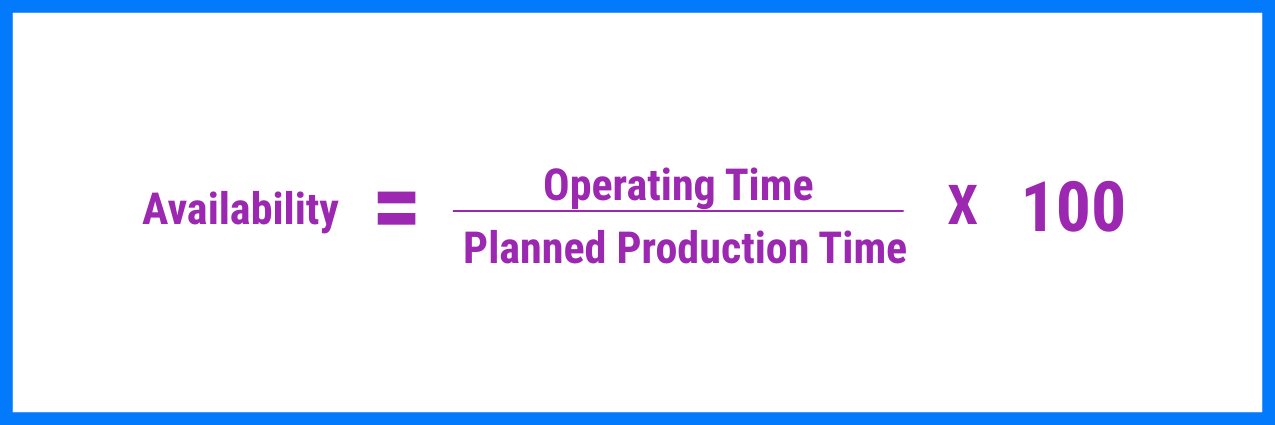

The Equipment Availability Formula

Equipment availability is calculated as: Availability (%) = (Operating TIme / Planned Production Time) × 100. This shows what percentage of planned production time the equipment was actually operating.

Operating Time is the actual run time when the equipment is producing. Planned Production Time is the total scheduled time minus any planned shutdowns (like breaks, scheduled maintenance, or shift changes). Multiply by 100.

An alternate way to express this is: Availability (%) = (Total Time - Downtime) / Total Time × 100, where Downtime includes all planned and unplanned stoppages during the scheduled production window.

Availability is one of three core components in the OEE formula (Availability × Performance × Quality). It specifically measures time losses from equipment downtime, whether planned or unplanned.

Equipment Availability Calculation Example

If a machine runs for 8 hours with 2 hours of downtime during a 10-hour shift, the availability calculation is (8 hours ÷ 10 hours) × 100 = 80%.

In availability calculations, downtime falls into two categories: planned downtime (scheduled maintenance, changeovers, breaks) and unplanned downtime (breakdowns, material shortages, quality issues). Some manufacturers exclude planned downtime from availability calculations to focus purely on unexpected losses, while others include all downtime to measure total equipment utilization.

Want to see your availability in real-time? Most factories lose 15-30% of production to uncommented stops. See what GlobalReader reveals about YOUR downtime →

Machine Availability vs. Utilization: What's the Difference?

Availability measures the percentage of scheduled time that equipment is operational, while utilization measures the percentage of total time (including unscheduled periods) that equipment is actually producing.

Availability focuses on scheduled production time only

Utilization includes all time (scheduled + unscheduled periods)

Stop guessing what caused downtime. GlobalReader's Operator tool captures downtime reasons in real-time →

What Factors Affect Equipment Availability?

Equipment availability is affected by downtime (both planned and unplanned), operating procedures, production scheduling, equipment design, and employee skills.

#1: Downtime (planned and unplanned)

The biggest contributor to low availability. Planned downtime includes maintenance, setups, and changeovers. Unplanned downtime covers breakdowns, failures, and accidents.

High availability depends on minimizing both types, but unplanned downtime has the most severe impact on production schedules.

#2: Reliability and maintainability MTBF and MTTR

Two critical metrics determine how often equipment fails and how quickly you can fix it:

MTBF (Mean Time Between Failures) - average time between breakdowns

MTTR (Mean Time To Repair) - average repair duration

High MTBF and low MTTR equal higher availability. If your machines break down frequently (low MTBF) or take hours to repair (high MTTR), your availability suffers.

Most factories don't realize how much availability they're losing to these factors. Track all availability losses automatically with GlobalReader Analytics - no manual spreadsheets needed.

#3: Active time lost (hidden production losses)

Not all downtime is obvious. Micro-stops, waiting for operators, or inefficient setups chip away at productive time without showing up in traditional downtime reports.

These small losses add up fast and can account for 10-20% of potential production capacity.

#4: Capacity utilization vs. availability

Availability measures uptime, but not how much capacity is being used. A machine might be available 95% of the time but only running at 60% capacity due to lack of orders, inefficient scheduling, or bottlenecks elsewhere.

High availability means nothing if you're not using that available time productively.

#5: Maintenance strategies

The right maintenance approach makes or breaks availability:

Preventive maintenance reduces unexpected failures through scheduled inspections

Predictive maintenance uses data to forecast issues before they cause downtime

Corrective maintenance is reactive and typically causes the longest downtimes

Factories using predictive maintenance typically see 25-30% less unplanned downtime compared to purely reactive approaches.

#6: External events and utility disruptions

External factors are harder to control but still need planning. Power outages, compressed air failures, supplier delays, extreme weather, and safety incidents can halt production instantly. These typically account for 5-15% of total downtime, varying by location and infrastructure reliability.

Planned vs. Unplanned Downtime

Planned downtime includes scheduled activities like maintenance and adjustments, while unplanned downtime results from unexpected events like equipment breakdowns or factory shutdowns.

Unplanned downtime is unexpected and disruptive. Equipment breakdowns, material shortages, quality issues requiring rework, operator errors, and emergency repairs all fall into this category.

The key difference is predictability. We covered the whole downtime topic here.

How to Improve Equipment Availability

The biggest availability gains come from measuring what's actually happening on your shop floor. Install GlobalReader OEE software with IoT sensors, and you'll immediately start capturing every downtime event in real-time.

Use Real-Time Monitoring and OEE Software

Real-time monitoring and OEE software track machine performance continuously, helping identify downtime causes as they happen. This enables faster response to breakdowns and supports predictive maintenance to prevent failures before they occur.

But here's where the real improvement begins: getting operators to log the reason for each stoppage. Was it a forklift occupied with another task while new material waited? A breakdown that needs maintenance? A changeover taking too long because SMED principles aren't in place yet?

Once you have this data, you can apply Lean Manufacturing principles to fix the root causes. Adjust your shop floor layout to reduce material handling delays. Implement SMED to cut changeover times. Address the bottlenecks that are actually costing you production time, not the ones you assume are problems.

Train Operators and Maintenance Teams

The pattern is simple: measure, identify, improve. Without real-time data and operator input, you're guessing. With it, you're making decisions that directly increase your equipment availability.

Training operators on Standard Operating Procedures (SOPs) and teaching maintenance teams to identify and troubleshoot equipment problems reduces both planned and unplanned downtime by improving response times and preventing errors.

Start Improving Your Equipment Availability Today

You've learned what availability is, how to calculate it, and what factors affect it. Now it's time to take action.

GlobalReader makes availability tracking effortless:

Install IoT sensors in hours (no IT team needed)

See real-time availability dashboards instantly

Identify hidden downtime automatically

Get predictive maintenance alerts before breakdowns

Three ways to get started:

Try our FREE DEMO → No financial commitment, explore the platform today

Start with the Starter Bundle (€109/month) → Hardware + Analytics + Real-time tracking

Talk to our team → Get a custom solution for your factory

““GlobalReader helped us increase availability from 65% to 89% in just 3 months by revealing downtime we didn’t even know existed.””

Read about the success of LEAX — Metal Industry Case Study

GlobalReader Tools for Availability Optimization

Stop losing production time to hidden downtime. Here's how GlobalReader helps you maximize availability:

Analytics → Track availability in real-time with automated dashboards

Operator Tool → Capture downtime reasons instantly from the shop floor

Maintenance → Prevent breakdowns with predictive maintenance alerts

See Pricing → Starter Bundle from €109/month (Hardware + Software included)

Ready to see your real availability? Start Your Free Demo →

-

Not exactly. Uptime is raw running time, while availability measures operating time against scheduled time.

-

Industry benchmarks vary, but 85–90% availability is often seen as world-class.

-

Availability focuses on downtime losses, while utilization measures how much of the available capacity is actually used.

-

Simple - you have to start tracking what machines are doing in real-time. Then train operators to give instant feedback, then make nessecary changes and repeat process.

-

Also simple: Use GlobalReader. OEE software. It comes together with hardware.

Our starter bundle is cheap and does not require IT crew or specially trained workforce to install. You can get it running in about 30 min to 1 hour.

Once you start seeing what is really happening on your shop floor only then you can make changes.