What Is Performance in OEE?

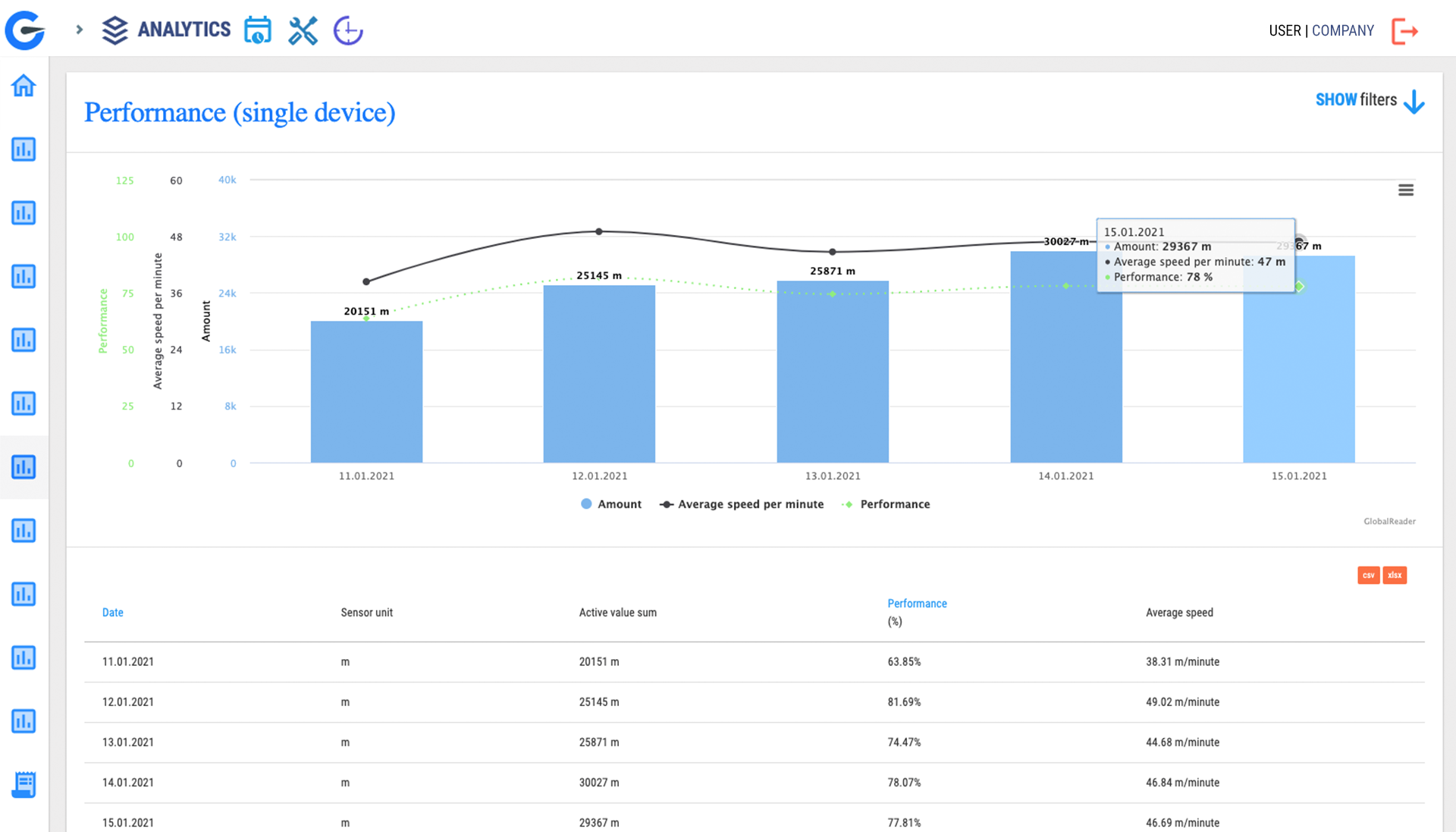

Performance in OEE measures how efficiently your machines run compared to their ideal speed. It answers the most asked question in manufacturing: “Are we producing as fast as we should when the machine is running?”

Summarize with AI

How to Calculate Performance in OEE

A high performance rate means your equipment is running close to its designed or product-specific speed. However, it’s important to note that not every product can be produced at the machine’s maximum capability — for example, a planer may process thin slats much faster than large cross-section beams. In such cases, speed limits are tied to the product's characteristics or quality requirements rather than the equipment itself.

Then again, a low performance rate indicates performance loss in Overall Equipment Efiiciency — often caused by micro-stoppages, reduced machine speed, or inconsistent operator handling.

The standard OEE formula to calculate a percentage of Machine Performance is:

Performance = (Ideal Cycle Time × Total Count) ÷ Operating Time x 100

In this formula:

Performance in OEE measures how fast you ran compared to the maximum possible speed of the equipment.

Ideal Cycle Time is the theoretical fastest time to produce one unit; multiplying it by Total Count gives the minimum possible time to make those pieces (Net Run Time).

Dividing this Net Run Time by the actual Run/Operating Time gives the speed loss factor: Performance = (Ideal Cycle Time × Total Count) / Run Time.

Some practitioners define a performance level as Actual Quantity divided by Theoretical Quantity at full speed during Run Time, which is mathematically equivalent if Target Quantity is computed from the ideal speed:

Performance = (Quantity/Target Quantity)

In that case:

Target Quantity = Run Time / Ideal Cycle Time, therefore:

Quantity = (Ideal Cycle Time × Actual Quantity) / Run Time.

So, “Performance = Quantity / Target Quantity” is only correct when “Target Quantity” is explicitly based on Ideal Cycle Time and actual Run Time; otherwise it can be misleading or inconsistent with standard OEE.

This shows how actual production speed compares with the theoretical maximum.

Example of Performance OEE Calculation

Ideal cycle time: 1.2 seconds per piece

Total pieces produced: 10,000

Operating time: 12,500 seconds

Performance = (1.2 × 10,000) ÷ 12,500 = 0.96 or 96%

That means your Performance rate in OEE is 96%, meaning the machine is producing slightly slower than its ideal speed.

How to Reduce Performance Loss in OEE

Performance losses can often be reduced by:

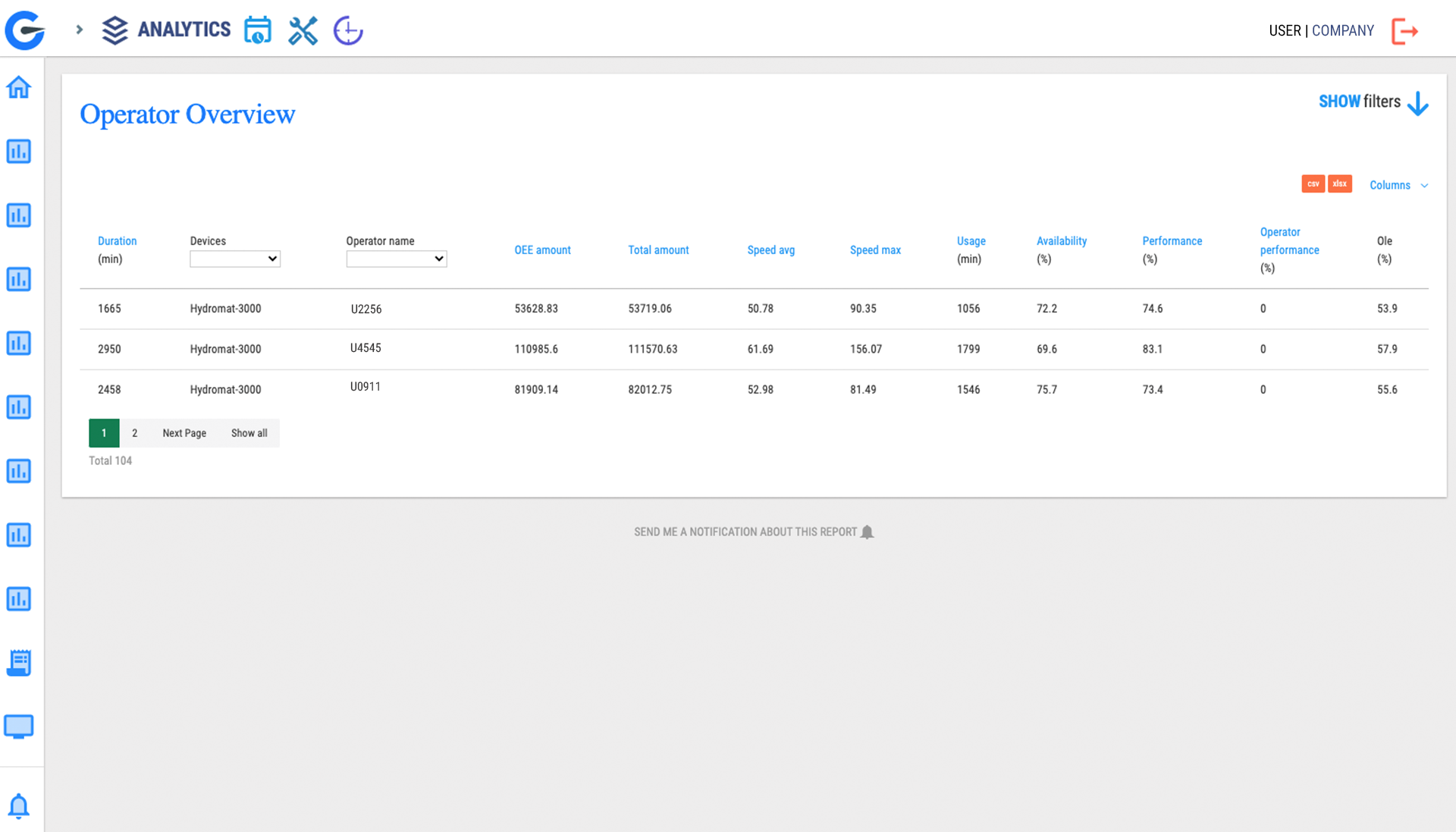

Tracking cycle times in real time using GlobalReader’s Operator App

Identifying repeated slow cycles or micro-stoppages

Calibrating tools and sensors regularly

Providing operator feedback dashboards to maintain target speed (Shop Floor feedback, Maintenance, Quality control, Analytics interruption report)

These actions keep machines running at their designed speed and help raise your overall OEE score. It is not all about performance though.

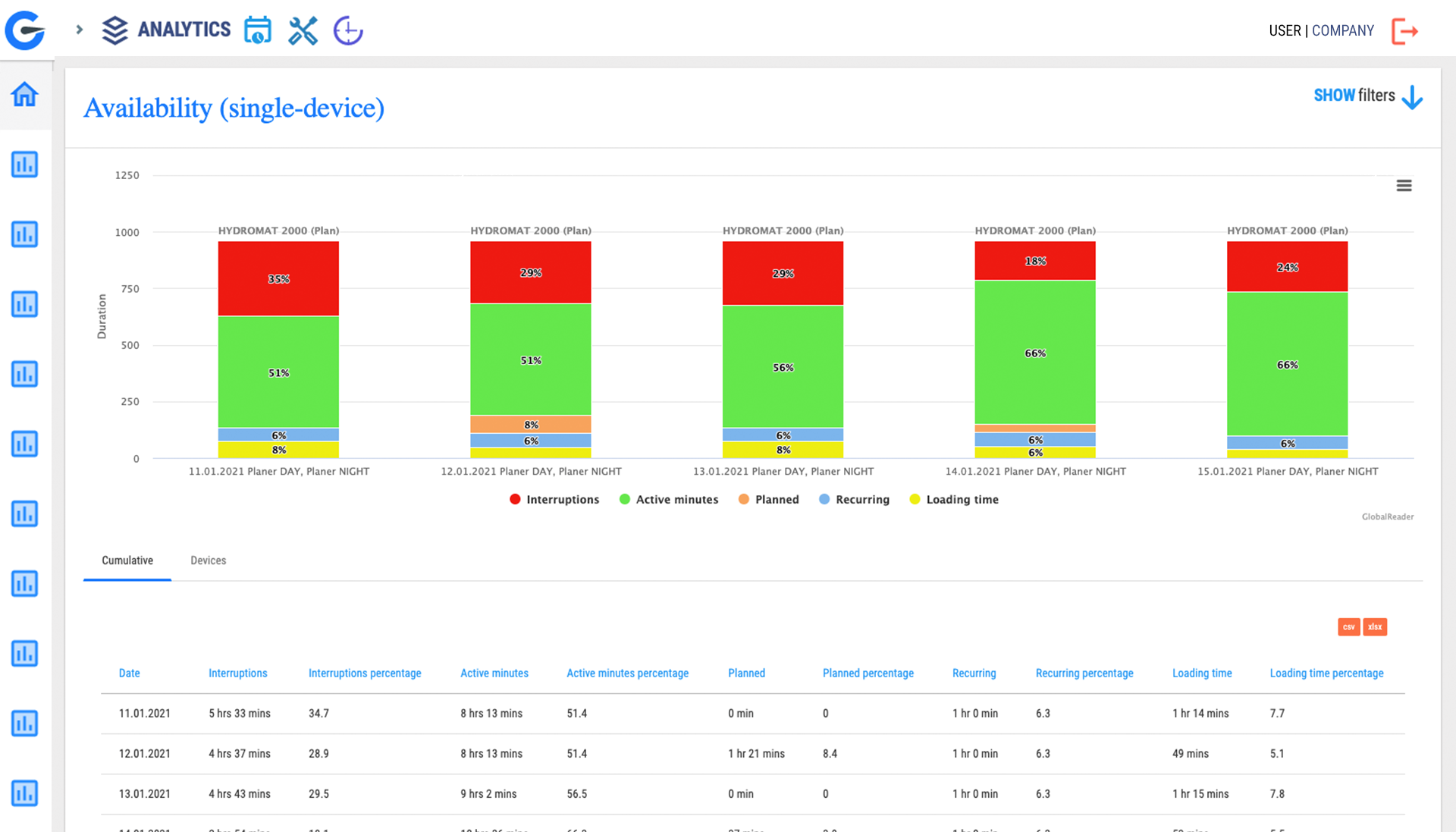

OEE has 2 more important factors to look at - Availability that is is the percentage of time a machine or system is operational and ready to perform its intended task during available production hours.

And Quality - a methodology for quantifying every euro a factory expends to ensure products meet specifications—or to deal with them when they don’t. Even that is not it to get a grip of the general topic. These oee components themselves bring more cool terms into play that you have to know about.

Things like Active Time and Loading Time as well (machine stopped but not an interruption yet) that contribute to different Lean principles that, in an ideal world, are shared across multiple levels like SMED or KAIZEN for continuous manufacturing improvement that you can use to be ahead of competitors. We know that it gets fuzzy and difficult really quickly. That is why actually GlobalReader got started. There was a huge problem on the table. Nobody knew what was actually going on and everybody blames someone else. Sounds familiar?

GlobalReader mission.

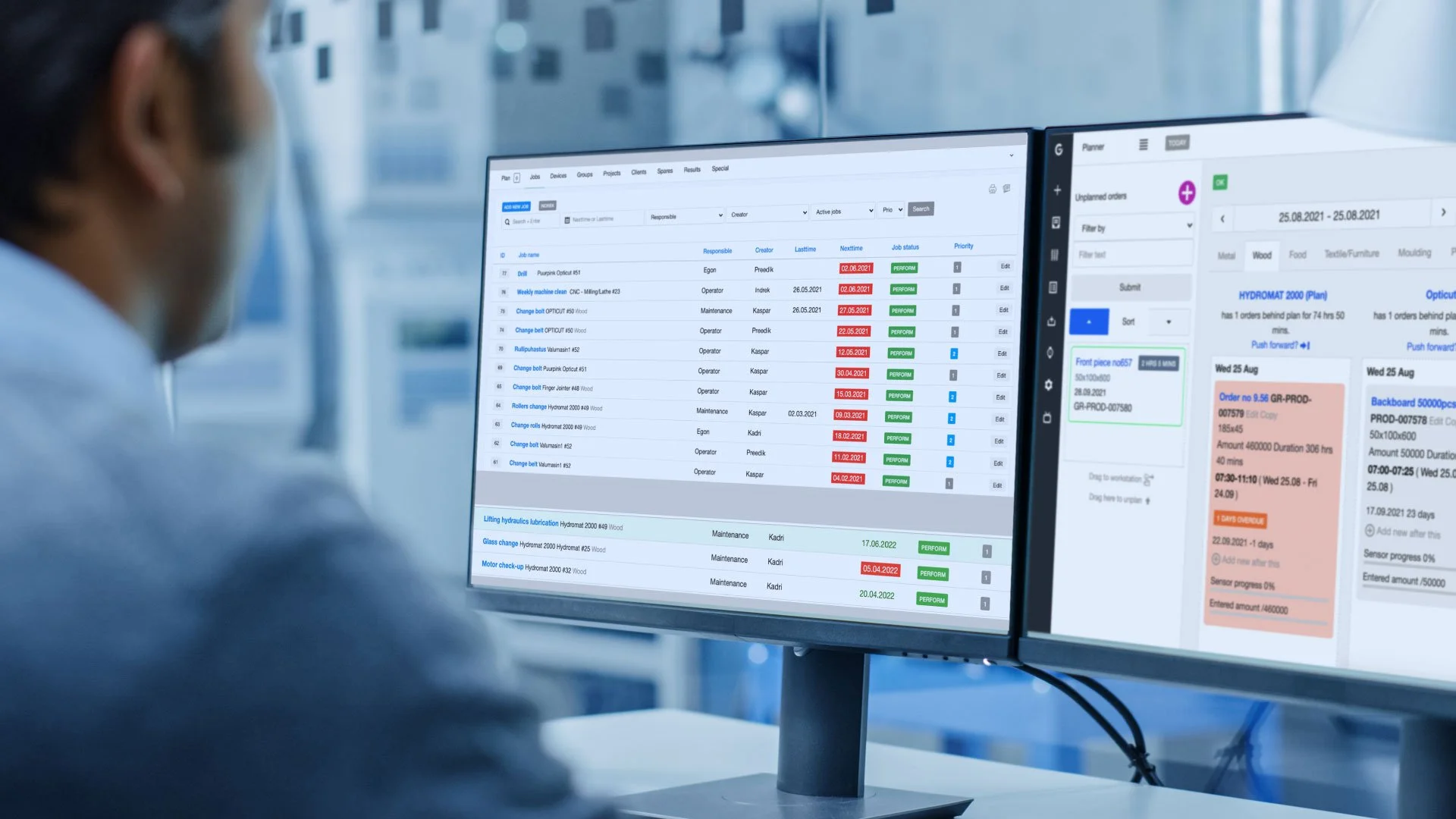

We inspire industry leaders to collect data around their production resources to increase efficiency, collaboration and to keep them ahead of their competition. If you want to be ahead of others and a true growing leader in your industry you better start measuring these OEE components. No, not manually in excel. That would be dumb. GlobalReader does that for you. See how it works yourself by trying the free demo. Just log in via Google or create an account.

Get In Touch!

If finding 10-20% of availability of even one machine in the next 2 months is anything of interest to you.

1. fill out the form.

2. Describe what machines you would want to measure!

3. Our team can then contact you and schedule a full demo of GlobalReader.