Get a comprehensive overview about OEE

Deep Dive Into Digitalisation

Everything about Lean Manufacturing

Read GlobalReader Case Studies about OEE

Everything about Data Analysis

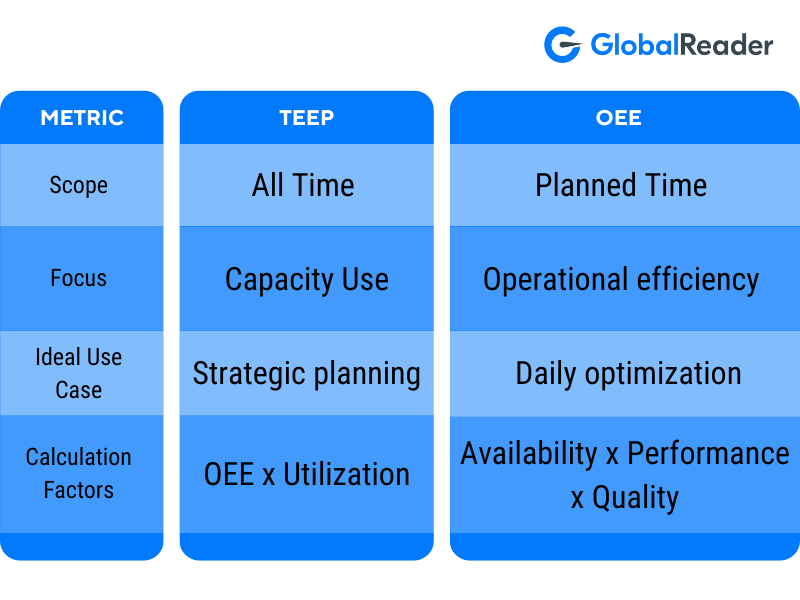

Everything about TEEP

All GlobalReader Posts

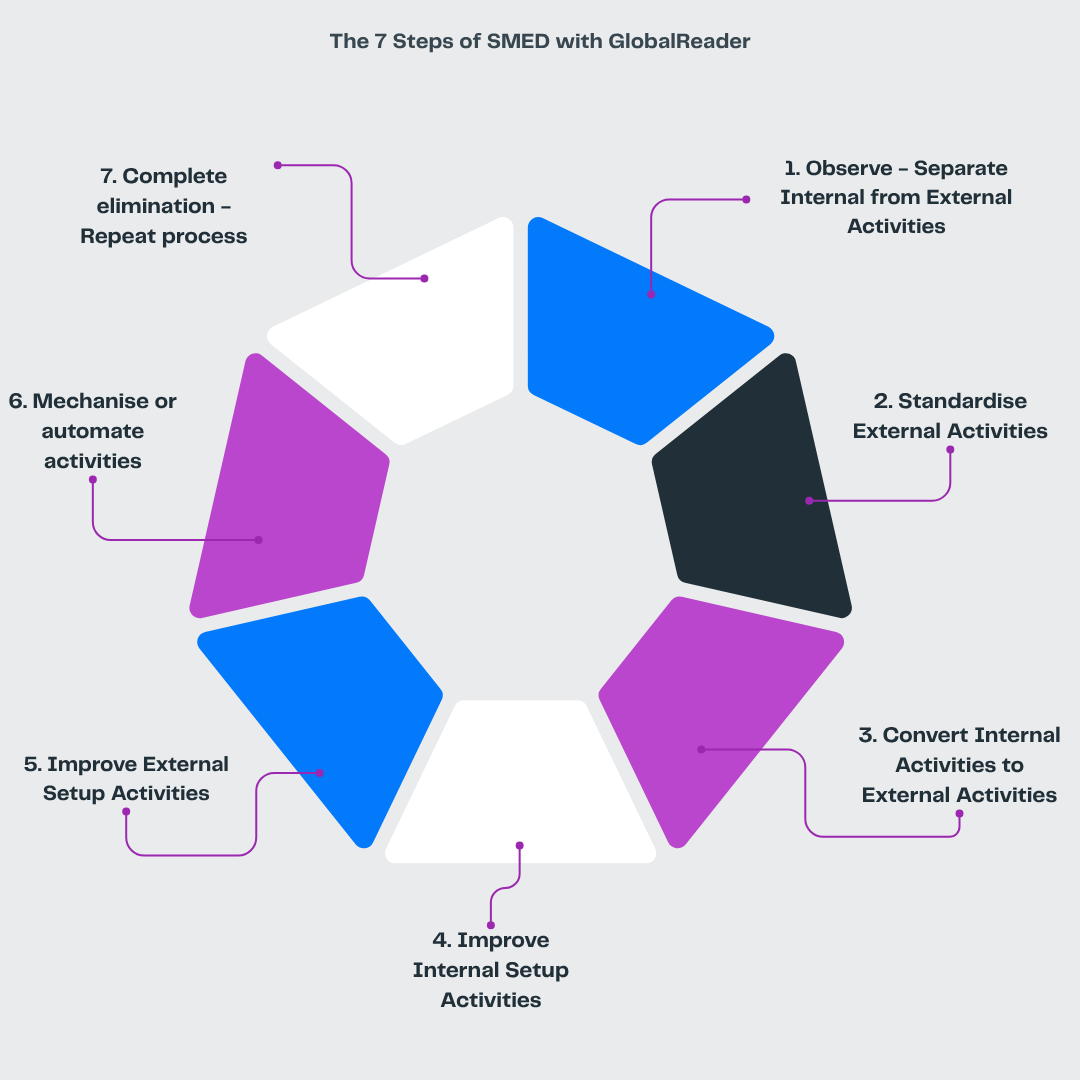

Kaizen for Continuous Manufacturing Improvement

The Kaizen process typically follows the PDCA cycle: Plan, Do, Check, Act. This cycle of continuous feedback and refinement ensures that improvements are sustainable and impactful over the long term.

Understanding the Six Big Losses in Manufacturing

Understanding and addressing the Six Big Losses in manufacturing is crucial for improving manufacturing efficiency and productivity.

5 Lean Manufacturing Principles

Real-time factory tracking combined with Lean Manufacturing principles is the easiest way to increase OEE (Overall Equipment Efficiency) and make your factory smart. Also drive your factory towards a sustainable future, where data-driven insights shape decisions and saves time and money.

Bridging Technology and Nature: Innovative ways real-time manufacturing data collection supports eco-friendly manufacturing

Merging lean manufacturing with Industry 4.0 is helping to change factories to be smarter and greener. By combining waste-cutting lean principles with advanced tech like real-time data analytics, manufacturers are increasing efficiency while cutting their environmental impact. This approach not only increases OEE but also significantly reduces waste and energy use, paving the way for a more sustainable manufacturing future. It's a win-win, better for business and kinder to the planet.