Get a comprehensive overview about OEE

Deep Dive Into Digitalisation

Everything about Lean Manufacturing

Read GlobalReader Case Studies about OEE

Everything about Data Analysis

Everything about TEEP

All GlobalReader Posts

Globalreader vs Competitors about TEEP

Discover how GlobalReader outperforms leading competitors like Vorne, MachineMetrics, and Tulip in TEEP optimisation. From real-time data to predictive maintenance and rapid deployment—see why manufacturers choose GlobalReader to unlock hidden capacity and drive profitability.

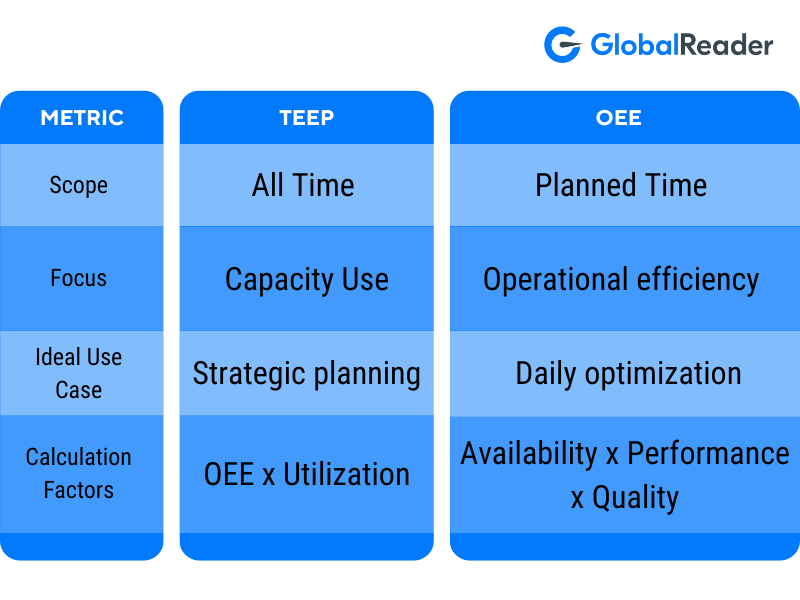

TEEP vs. Other Metrics – When to Focus on Each

While TEEP (Total Effective Equipment Performance) and OEE (Overall Equipment Effectiveness) are closely related, each serves a distinct purpose. Understanding their differences—and when to prioritise one over the other—can help you optimise your manufacturing operations more effectively.

A step-by-step guide to What is TEEP (Total Effective Equipment Performance)

TEEP is calculated by multiplying four factors: Availability, Performance, Quality, and Utilization to provide a comprehensive view of how effectively your operation uses all available time, not just the planned production time. Since OEE already includes Availability, Performance, and Quality, Utilisation is the missing factor needed to understand total equipment effectiveness over full calendar time. By measuring both equipment efficiency and utilisation, it helps you uncover the true capacity of your plant.